5 Air Force Logistics Tips

Introduction to Air Force Logistics

The Air Force logistics system is a complex network of processes and procedures designed to ensure the efficient and effective management of resources, equipment, and personnel. Effective logistics management is critical to the success of Air Force operations, as it enables the rapid deployment of troops and equipment, minimizes downtime, and maximizes the availability of critical assets. In this blog post, we will explore five key tips for optimizing Air Force logistics, with a focus on improving efficiency, reducing costs, and enhancing overall performance.

Tip 1: Implement a Predictive Maintenance Program

A predictive maintenance program uses advanced analytics and machine learning algorithms to identify potential equipment failures before they occur. This approach enables maintenance teams to schedule repairs and replacements during periods of low activity, reducing downtime and minimizing the impact on operations. By implementing a predictive maintenance program, Air Force logistics teams can: * Reduce equipment failures by up to 50% * Decrease maintenance costs by up to 30% * Improve equipment availability by up to 20% Some of the key technologies used in predictive maintenance include: * Sensors and IoT devices to monitor equipment performance * Machine learning algorithms to analyze data and predict failures * Cloud-based platforms to store and analyze data

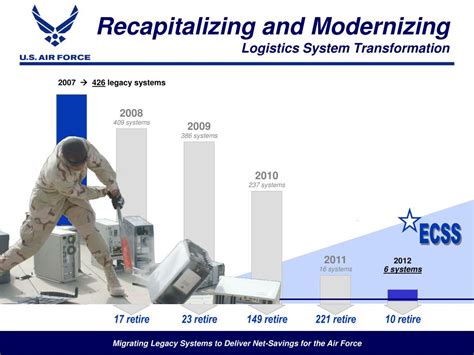

Tip 2: Optimize Supply Chain Management

Effective supply chain management is critical to ensuring the timely delivery of critical assets and equipment. Air Force logistics teams can optimize supply chain management by: * Implementing just-in-time delivery systems to minimize inventory levels * Using advanced analytics to predict demand and optimize inventory levels * Developing strategic partnerships with suppliers to improve delivery times and reduce costs Some of the key benefits of optimizing supply chain management include: * Reduced inventory levels * Improved delivery times * Decreased costs

Tip 3: Leverage Digital Twin Technology

Digital twin technology involves creating a virtual replica of a physical asset or system, which can be used to simulate performance, predict failures, and optimize maintenance. Air Force logistics teams can leverage digital twin technology to: * Improve equipment performance and reduce downtime * Optimize maintenance schedules and reduce costs * Enhance situation awareness and improve decision-making Some of the key benefits of digital twin technology include: * Improved equipment performance * Reduced maintenance costs * Enhanced situation awareness

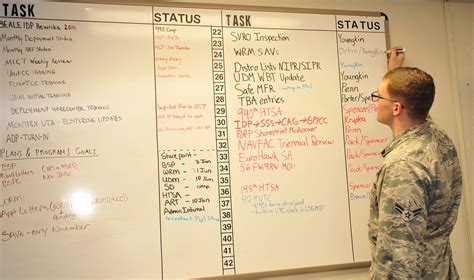

Tip 4: Implement a Total Quality Management Program

A total quality management (TQM) program is a systematic approach to quality management that involves all members of the organization. Air Force logistics teams can implement a TQM program to: * Improve quality and reduce defects * Enhance customer satisfaction and improve relationships * Reduce costs and improve efficiency Some of the key principles of TQM include: * Continuous improvement: Encouraging all members of the organization to identify areas for improvement * Customer focus: Focusing on meeting the needs of customers and stakeholders * Employee empowerment: Empowering employees to take ownership of quality and improvement

Tip 5: Develop a Cybersecurity Plan

Cybersecurity is a critical component of Air Force logistics, as it involves protecting critical assets and equipment from cyber threats. Air Force logistics teams can develop a cybersecurity plan to: * Protect critical assets and equipment from cyber threats * Prevent data breaches and protect sensitive information * Ensure compliance with cybersecurity regulations and standards Some of the key components of a cybersecurity plan include: * Risk assessment: Identifying potential cyber threats and vulnerabilities * Incident response: Developing a plan to respond to cyber incidents * Employee training: Providing training and awareness programs to employees

💡 Note: Implementing these tips requires a thorough understanding of Air Force logistics operations and the ability to analyze complex data and systems.

In summary, optimizing Air Force logistics requires a comprehensive approach that involves implementing predictive maintenance programs, optimizing supply chain management, leveraging digital twin technology, implementing total quality management programs, and developing cybersecurity plans. By following these tips, Air Force logistics teams can improve efficiency, reduce costs, and enhance overall performance.

What is the primary goal of Air Force logistics?

+

The primary goal of Air Force logistics is to ensure the efficient and effective management of resources, equipment, and personnel to support Air Force operations.

What is predictive maintenance, and how does it benefit Air Force logistics?

+

Predictive maintenance uses advanced analytics and machine learning algorithms to identify potential equipment failures before they occur, reducing downtime and minimizing the impact on operations.

How can Air Force logistics teams optimize supply chain management?

+

Air Force logistics teams can optimize supply chain management by implementing just-in-time delivery systems, using advanced analytics to predict demand, and developing strategic partnerships with suppliers.

Related Terms:

- Logistics Plans Air Force salary

- Air Force Logistics jobs

- Logistics plans Air Force Reddit

- Air Force Logistics Officer

- 2g0x1 logistics plans

- air force logistics plan template