5 CAM Jobs

Introduction to CAM Jobs

The Computer-Aided Manufacturing (CAM) industry has experienced significant growth in recent years, driven by advancements in technology and the increasing demand for automated manufacturing processes. As a result, various job opportunities have emerged in this field, offering a range of career paths for individuals with different skill sets and interests. In this article, we will explore five CAM jobs that are currently in demand, highlighting their key responsibilities, required skills, and potential career paths.

CAM Software Developer

A CAM software developer is responsible for designing, developing, and testing software programs used in computer-aided manufacturing. Their primary goal is to create efficient and user-friendly software that can simplify the manufacturing process, reduce errors, and improve productivity. To become a CAM software developer, one should possess strong programming skills, particularly in languages such as C++, Java, or Python, as well as experience with CAD/CAM systems and software development methodologies.

💻 Note: A degree in computer science, engineering, or a related field is often required for this position.

CAM Engineer

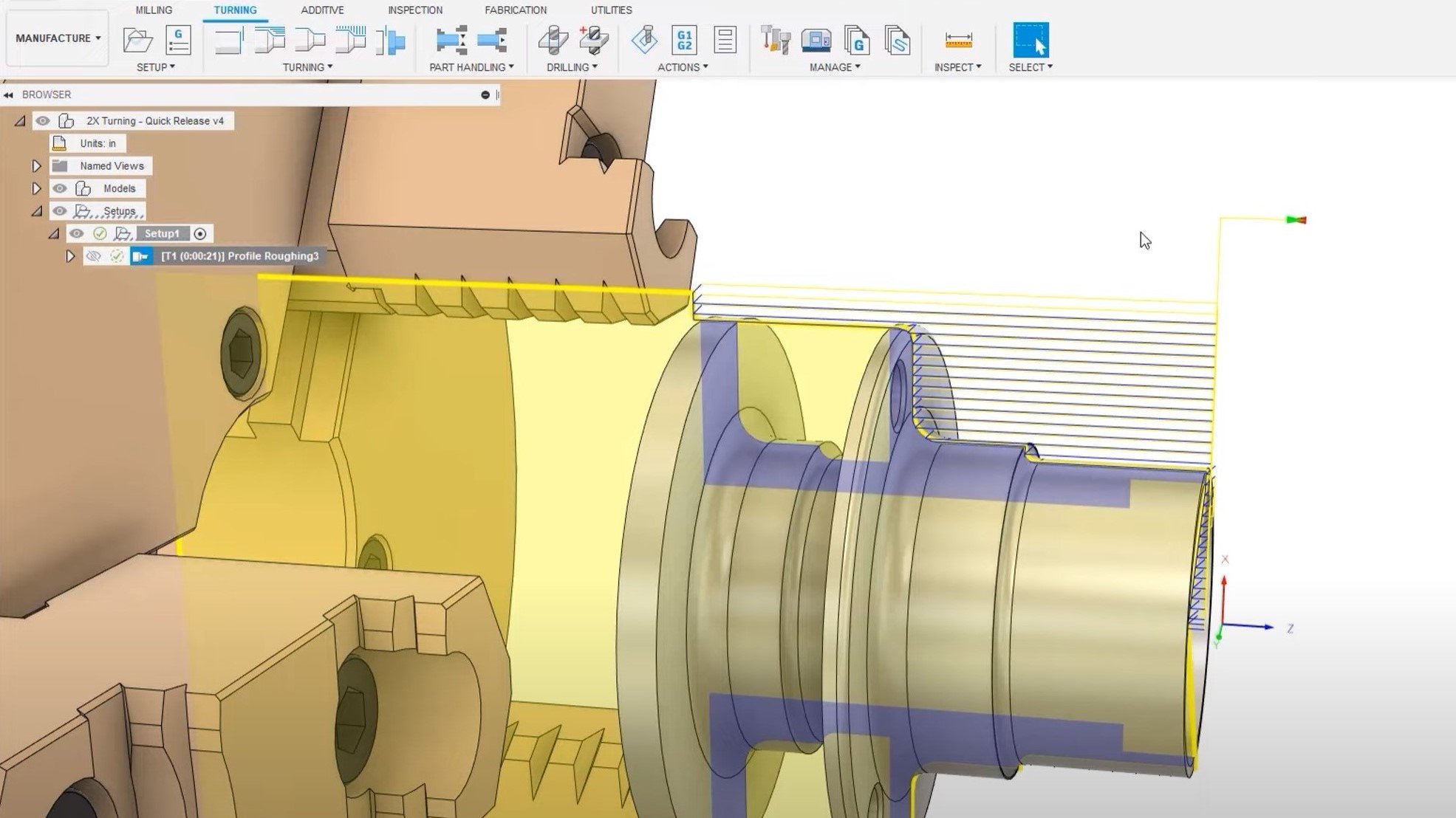

A CAM engineer plays a crucial role in the manufacturing process, as they are responsible for designing, developing, and implementing manufacturing processes using CAM software. Their key responsibilities include creating G-code programs, designing machine tool paths, and optimizing manufacturing processes to improve efficiency and reduce costs. To become a CAM engineer, one should have a strong understanding of manufacturing processes, CAD/CAM systems, and G-code programming, as well as experience with machine tools and manufacturing equipment.

CNC Machinist

A CNC (Computer Numerical Control) machinist operates and maintains CNC machines, which are used to manufacture precision parts and products. Their primary responsibilities include setting up and operating CNC machines, editing G-code programs, and inspecting finished parts to ensure they meet quality standards. To become a CNC machinist, one should have experience with CNC machines, G-code programming, and manufacturing processes, as well as a strong understanding of mathematics and geometric dimensioning.

Manufacturing Engineer

A manufacturing engineer is responsible for designing, developing, and implementing manufacturing systems and processes. Their key responsibilities include designing production lines, developing manufacturing procedures, and optimizing manufacturing processes to improve efficiency and reduce costs. To become a manufacturing engineer, one should have a strong understanding of manufacturing processes, CAD/CAM systems, and industrial engineering principles, as well as experience with machine tools and manufacturing equipment.

Quality Control Inspector

A quality control inspector is responsible for ensuring that manufactured products meet quality standards and specifications. Their primary responsibilities include inspecting finished products, identifying defects and imperfections, and developing quality control procedures to prevent defects. To become a quality control inspector, one should have experience with quality control procedures, manufacturing processes, and statistical process control, as well as a strong understanding of mathematics and geometric dimensioning.

📝 Note: A degree in engineering, quality control, or a related field is often required for this position.

The following table summarizes the key responsibilities, required skills, and potential career paths for each of the five CAM jobs:

| Job Title | Key Responsibilities | Required Skills | Potential Career Paths |

|---|---|---|---|

| CAM Software Developer | Designing, developing, and testing CAM software | Programming skills, CAD/CAM systems, software development methodologies | Senior software developer, technical lead, software architect |

| CAM Engineer | Designing, developing, and implementing manufacturing processes | CAD/CAM systems, G-code programming, manufacturing processes | Senior engineer, technical lead, manufacturing manager |

| CNC Machinist | Operating and maintaining CNC machines | CNC machines, G-code programming, manufacturing processes | Senior machinist, CNC programmer, manufacturing supervisor |

| Manufacturing Engineer | Designing, developing, and implementing manufacturing systems and processes | CAD/CAM systems, industrial engineering principles, manufacturing processes | Senior engineer, technical lead, manufacturing manager |

| Quality Control Inspector | Inspecting finished products, identifying defects and imperfections | Quality control procedures, manufacturing processes, statistical process control | Senior inspector, quality control supervisor, manufacturing manager |

In summary, the five CAM jobs discussed in this article offer a range of career paths for individuals with different skill sets and interests. By understanding the key responsibilities, required skills, and potential career paths for each job, individuals can make informed decisions about their career goals and pursue opportunities in the CAM industry. With the increasing demand for automated manufacturing processes, the CAM industry is expected to continue growing, providing numerous job opportunities for skilled professionals.

Related Terms:

- camcare part time jobs

- Related searches camcare nurse jobs