MIG Stands For Metal Inert Gas

Introduction to MIG Welding

MIG stands for Metal Inert Gas, a welding process that uses a continuous wire feed as the electrode and an inert gas to shield the arc. This process is also known as Gas Metal Arc Welding (GMAW). The MIG welding process is widely used in various industries, including automotive, construction, and manufacturing, due to its high speed, versatility, and ability to produce high-quality welds.

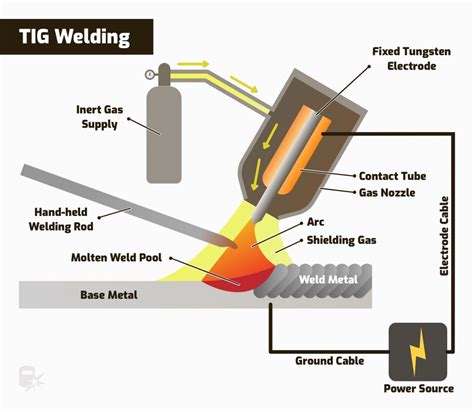

How MIG Welding Works

The MIG welding process involves the use of a welding gun, a wire feed system, and a shielding gas. The welding gun is connected to a power source and a wire feed system, which feeds a continuous wire electrode through the gun. The shielding gas, typically argon or helium, is fed through the gun and surrounds the arc, protecting it from atmospheric gases that can cause porosity and other defects in the weld. The wire electrode is continuously fed through the gun and into the weld pool, where it is melted and fused to the base metal.

Benefits of MIG Welding

MIG welding offers several benefits, including: * High speed: MIG welding is a fast process, making it ideal for high-volume production. * Versatility: MIG welding can be used on a variety of metals, including steel, aluminum, and stainless steel. * High-quality welds: MIG welding produces high-quality welds with minimal porosity and other defects. * Ease of use: MIG welding is a relatively easy process to learn, making it a great choice for beginners.

MIG Welding Equipment

The equipment needed for MIG welding includes: * A welding gun, which is used to feed the wire electrode and shielding gas into the weld area. * A wire feed system, which feeds the wire electrode through the gun. * A power source, which provides the electrical energy needed to melt the wire electrode and base metal. * A shielding gas, which protects the arc from atmospheric gases. * A welding helmet, which protects the welder’s eyes and face from the arc.

MIG Welding Techniques

There are several MIG welding techniques, including: * Short-circuiting: This technique involves using a short arc length and a high wire feed speed to produce a weld with a smooth, flat appearance. * Spray transfer: This technique involves using a longer arc length and a higher wire feed speed to produce a weld with a rough, irregular appearance. * Pulse welding: This technique involves using a pulsed arc to produce a weld with a smooth, flat appearance.

MIG Welding Safety

MIG welding safety is crucial to prevent injuries and ensure a safe working environment. Some safety precautions to take include: * Wearing a welding helmet to protect the eyes and face from the arc. * Wearing heat-resistant gloves to protect the hands from heat and sparks. * Wearing protective clothing to protect the body from heat and sparks. * Ensuring good ventilation to prevent inhalation of fumes and particles.

🔍 Note: Always follow the manufacturer's instructions and safety guidelines when using MIG welding equipment.

MIG Welding Applications

MIG welding has a wide range of applications, including: * Automotive repair: MIG welding is used to repair and manufacture automotive parts, such as body panels and frames. * Construction: MIG welding is used to weld steel beams and other structural elements in building construction. * Manufacturing: MIG welding is used to manufacture a variety of products, including machinery, equipment, and consumer goods.

| Application | Description |

|---|---|

| Automotive repair | MIG welding is used to repair and manufacture automotive parts. |

| Construction | MIG welding is used to weld steel beams and other structural elements. |

| Manufacturing | MIG welding is used to manufacture a variety of products. |

In summary, MIG welding is a versatile and widely used welding process that offers several benefits, including high speed, versatility, and high-quality welds. With the right equipment and techniques, MIG welding can be used in a variety of applications, from automotive repair to manufacturing. By following safety guidelines and manufacturer’s instructions, welders can ensure a safe and successful welding experience.

What is MIG welding?

+

MIG welding is a welding process that uses a continuous wire feed as the electrode and an inert gas to shield the arc.

What are the benefits of MIG welding?

+

The benefits of MIG welding include high speed, versatility, and high-quality welds.

What safety precautions should be taken when MIG welding?

+

Some safety precautions to take when MIG welding include wearing a welding helmet, heat-resistant gloves, and protective clothing, and ensuring good ventilation.

Related Terms:

- What does TIG stand for

- Mikoyan and Gurevich

- mig 50 fighter

- list of mig aircraft

- top gun mig 28