5 OCS Locations

Introduction to OCS Locations

When it comes to Oil Condition Systems (OCS), understanding the various locations where these systems can be implemented is crucial for effective maintenance and operation. OCS locations are diverse, ranging from industrial settings to marine environments, each with its unique challenges and requirements. In this blog post, we will delve into 5 key OCS locations, exploring their characteristics, challenges, and the importance of oil condition monitoring in these settings.

1. Industrial Manufacturing Facilities

Industrial manufacturing facilities are among the most common locations for OCS. These environments are characterized by high machinery usage, which necessitates regular oil condition monitoring to prevent equipment failure and downtime. Implementing an OCS in such facilities helps in predictive maintenance, allowing for the early detection of potential issues before they escalate into major problems. This not only saves costs associated with repairs and replacements but also ensures continuous production, thereby maintaining productivity and efficiency.

2. Power Generation Plants

Power generation plants are critical infrastructure that require uninterrupted operation to meet energy demands. The use of OCS in these plants is vital for monitoring the condition of turbine oils, hydraulic fluids, and other lubricants crucial for the smooth operation of generators and turbines. Real-time monitoring enables immediate response to changes in oil condition, preventing overheating, corrosion, and wear on moving parts, which could lead to power outages and significant economic losses.

3. Marine Vessels

Marine vessels present a unique set of challenges for OCS due to the harsh marine environment and the critical nature of their operations. Oil condition monitoring on marine vessels is essential for the prevention of engine failure, which can lead to costly repairs, operational downtime, and even safety risks. Regular monitoring of lubricant condition helps in identifying contamination, degradation, or other issues early on, ensuring the vessel’s engines and machinery remain in good working condition throughout their voyages.

4. Wind Farms

Wind farms, with their growing presence in the renewable energy sector, also benefit significantly from OCS. The gearboxes and generators in wind turbines require high-quality lubrication to operate efficiently and reliably. Implementing an OCS in wind farms helps in extending the lifespan of these critical components by continuously monitoring the condition of the lubricants. This proactive approach to maintenance reduces downtime, improves energy production, and lowers the overall cost of wind energy production.

5. Automotive and Fleet Maintenance

In the context of automotive and fleet maintenance, OCS plays a crucial role in vehicle health and performance. By monitoring the condition of engine oils, transmission fluids, and other lubricants, fleet owners can optimize vehicle maintenance schedules, reduce the risk of unexpected breakdowns, and improve fuel efficiency. This is particularly important for commercial fleets, where uptime and reliability are key to operational success and customer satisfaction.

📝 Note: Regular oil condition monitoring can significantly reduce maintenance costs and extend the lifespan of machinery and vehicles across all these locations.

In summary, the implementation of Oil Condition Systems across various locations is not just beneficial but essential for maintaining efficiency, reducing costs, and ensuring the longevity of equipment and vehicles. Whether in industrial facilities, power generation plants, marine vessels, wind farms, or automotive and fleet maintenance, the strategic use of OCS can lead to significant operational improvements.

What is the primary benefit of using OCS in industrial settings?

+

The primary benefit is the ability to perform predictive maintenance, reducing downtime and increasing overall productivity.

How does OCS contribute to the efficiency of power generation plants?

+

OCS helps in the real-time monitoring of lubricant conditions, preventing potential failures and ensuring continuous operation.

What role does OCS play in the maintenance of marine vessels?

+

OCS is crucial for preventing engine failure by identifying issues with lubricants early on, ensuring the vessel’s operational safety and efficiency.

Related Terms:

- where is army ocs held

- army ocs locations

- army ocs website

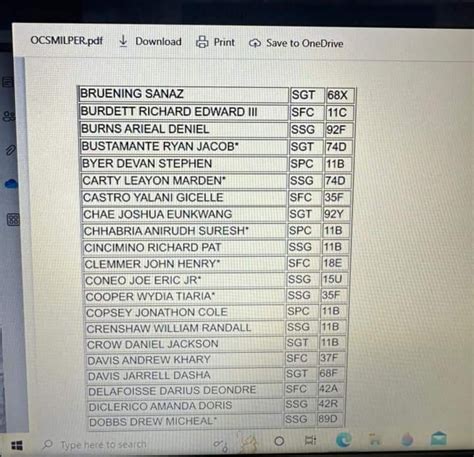

- army ocs selection list

- army ocs branch list

- army ocs portal