5 Tips Welders

Introduction to Welding

Welding is a complex process that requires a great deal of skill and practice to master. Whether you’re a seasoned professional or just starting out, there are several key tips to keep in mind to ensure that your welds are strong, consistent, and of high quality. In this article, we’ll explore five essential tips for welders, covering topics such as safety, equipment, and technique.

Safety First

Before we dive into the nitty-gritty of welding techniques, it’s essential to discuss safety. Welding can be a hazardous activity, and it’s crucial to take the necessary precautions to protect yourself from injury. This includes wearing proper protective gear, such as a welding helmet, gloves, and a fire-resistant jacket. Additionally, make sure you’re working in a well-ventilated area, and keep a fire extinguisher nearby.

Choosing the Right Equipment

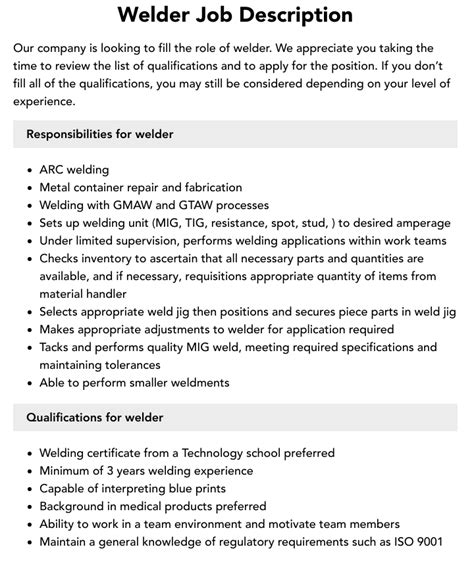

Having the right equipment is vital for producing high-quality welds. This includes not only the welder itself but also the consumables, such as welding rods or wire. When selecting a welder, consider the type of welding you’ll be doing most often, as well as the thickness of the materials you’ll be working with. For example, if you’ll be welding thick steel plates, you’ll need a welder that can handle high currents.

Technique is Everything

Proper technique is essential for producing strong, consistent welds. This includes maintaining the correct welding angle, using the right welding speed, and keeping the arc length consistent. It’s also important to keep the weld area clean, free from dirt, oil, and other contaminants that can weaken the weld. By following these guidelines, you can ensure that your welds are of the highest quality.

Practice Makes Perfect

Like any skill, welding takes practice to master. Don’t be discouraged if your early attempts at welding don’t turn out as expected. Keep practicing, and you’ll soon see improvement. It’s also a good idea to seek guidance from experienced welders, who can offer valuable tips and advice.

Troubleshooting Common Issues

Even with proper technique and equipment, issues can still arise. Common problems include porosity, lack of penetration, and warpage. To troubleshoot these issues, consider the following: * Porosity: Check for contamination in the weld area, and ensure that the shielding gas is flowing properly. * Lack of penetration: Increase the welding current, or use a thicker welding rod. * Warpage: Use a heat sink to absorb excess heat, or weld in a specific pattern to minimize distortion.

🔍 Note: Always refer to the manufacturer's instructions for specific troubleshooting guidance, as different welders and materials may require unique solutions.

In summary, to become a skilled welder, it’s essential to prioritize safety, choose the right equipment, master proper technique, practice regularly, and be able to troubleshoot common issues. By following these tips, you’ll be well on your way to producing high-quality welds that will serve you well in your welding endeavors.

What is the most important safety precaution in welding?

+

The most important safety precaution in welding is wearing proper protective gear, including a welding helmet, gloves, and a fire-resistant jacket.

What is the difference between MIG and TIG welding?

+

MIG (GMAW) welding uses a continuous wire feed, while TIG (GTAW) welding uses a tungsten electrode and separate filler rod. MIG welding is often faster and more convenient, while TIG welding offers more precision and control.

How do I prevent porosity in my welds?

+

To prevent porosity, ensure that the weld area is clean and free from contamination, and that the shielding gas is flowing properly. You can also try increasing the welding current or using a thicker welding rod.

Related Terms:

- job opportunities for welding

- welder job duties and responsibilities

- where do welders work

- working conditions of a welder

- welding scope of work

- working conditions for welding